Furnace Troubleshooting: Diagnose and Fix Common Heating Problems

Furnace troubleshooting is a step-by-step approach to find out why your heating system isn’t producing warmth, pinpoint the part or setting at fault, and decide whether a safe DIY check can fix it or if you need a pro. This guide walks homeowners through the most common furnace issues, how parts like the thermostat, blower motor, flame sensor, and filters work together, and what practical steps to take before calling for service. You’ll get safety-first checks, simple fixes you can do without special tools, and clear signs for when to stop and call a technician. We cover five core areas: no-heat diagnosis, cold-air delivery, short cycling, ignition/pilot problems, and reading error codes — each with focused checks, quick action lists, and tables that match symptoms to likely solutions. Keywords like furnace troubleshooting, furnace repair tips, and furnace maintenance checklist are used so you can find the steps you need and tell DIY triage apart from professional repair.

Why isn’t my furnace heating? Key causes and quick fixes

When a furnace won’t heat, the usual culprits are a few predictable things: thermostat settings or power problems, ignition or pilot failures, blocked airflow from dirty filters, or interruptions to gas or electricity. Thinking of the system as a chain — thermostat → ignition/combustion → heat transfer to ductwork — makes it easier to find where it’s breaking. Start with non-invasive checks that often restore heat quickly, then move to professional diagnostics for safety-critical parts like gas valves or suspected heat-exchanger damage. Below are the first checks and three quick fixes that commonly bring a furnace back to life.

Immediate checks and quick fixes to try first:

- Make sure the thermostat is set to Heat, the set temperature is above room temperature, and the thermostat has power.

- Confirm the furnace power switch is on and the circuit breaker hasn’t tripped.

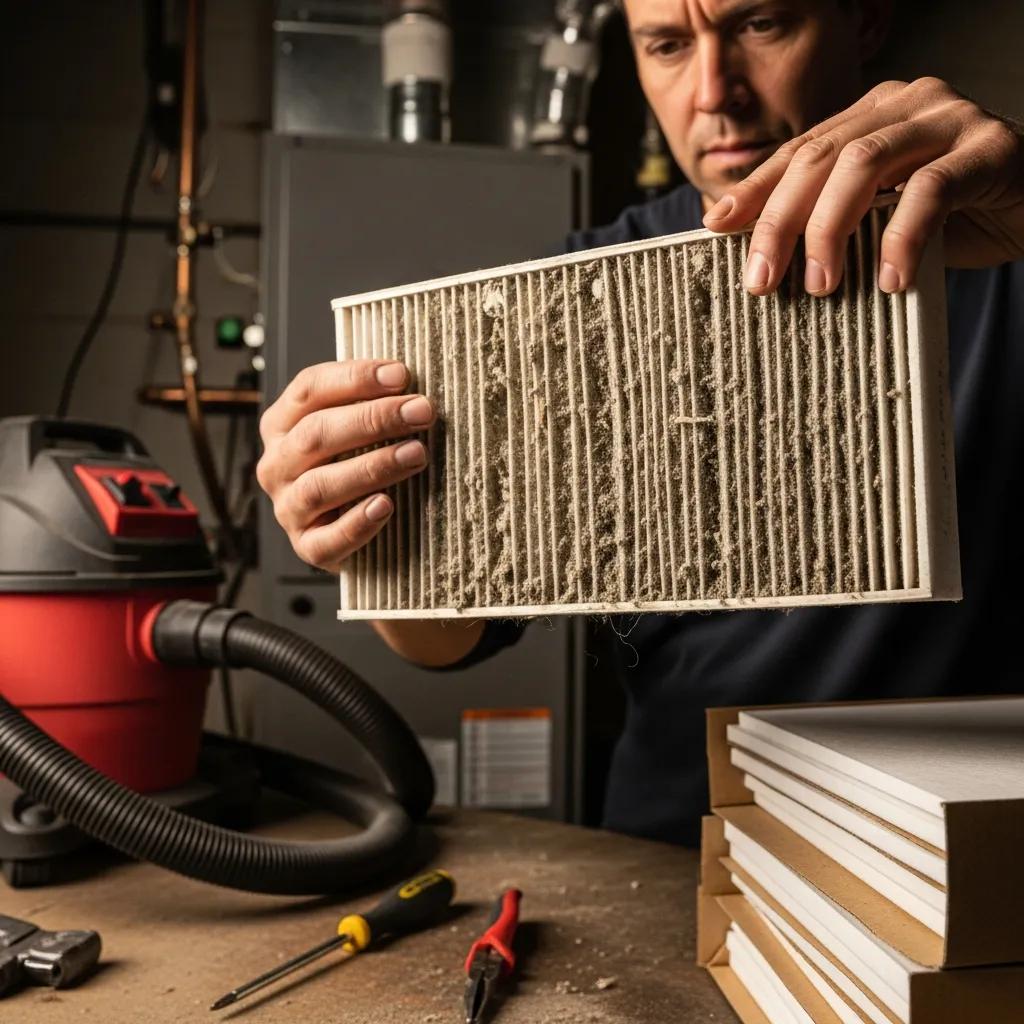

- Look at the air filter and replace it if it’s visibly dirty — clogged filters often prevent normal ignition cycles.

These steps usually rule out simple problems and point to whether the issue is electrical, control-related, or combustion-related. The next section walks through thermostat checks step by step so you can test safely and clearly.

Check thermostat settings and wiring

The thermostat is the system’s command center: it reads room temperature and tells the furnace when to run. Start by confirming the mode and setpoint, replace batteries if the display is blank, and verify any Wi‑Fi or smart‑thermostat indicators look normal. If the thermostat appears powered and set correctly but the furnace doesn’t respond, remove the cover and look for loose wires or damaged connectors — do not touch exposed conductors. Label or photograph wires before you close the cover so a technician has a clear reference. If a reset or battery swap fixes things, keep an eye on it; ongoing communication errors or charred connectors mean you should call a pro for thermostat or control‑board service. Proper thermostat placement also affects short cycling and temperature accuracy, which we address next along with airflow tips.

Inspect air filters and airflow components

Restricted airflow from a clogged filter can force safety sensors to shut down burners to prevent overheating the heat exchanger. Locate the filter at the furnace intake or a return grille, turn off power, slide the filter out, and look for heavy dust, pet hair, or discoloration. Hold the filter up to a light — if little or no light passes, replace it. Use the correct size and a MERV rating suitable for your system; higher MERVs filter better but can restrict airflow on older blowers, so follow the manufacturer’s guidance. If replacing the filter restores operation, set a regular check schedule. If airflow is still weak, a duct or blower inspection by a technician is the next step to find obstructions or motor issues.

Why is my furnace blowing cold air? Causes and practical solutions

If the furnace runs but blows cold air, it usually means combustion isn’t happening (no flame) or the fan is moving air without heat exchange. Common causes include restricted airflow triggering a high‑limit trip, a failed igniter or pilot, limit switch activation, or the blower running in continuous fan mode. Start with the easiest, safest checks: filter condition, thermostatfan setting, and visible signs of ignition. Working in that order speeds diagnosis and prevents unnecessary part replacement.

Follow this prioritized troubleshooting sequence:

These steps help you determine whether the system is producing warm combustion air or simply circulating cool house air. The following H3 sections show safe, practical how‑tos for checking filters and the blower/limit switch.

Dirty air filter and restricted airflow

Dirty filters can starve the furnace of return air, causing the heat exchanger to overheat and trip the limit switch. The burners stop while the blower keeps running, which produces cold airflow. To inspect: power down the unit, remove the filter, and look for a dense build‑up of dust or debris. Gently tap disposable filters to see if particles fall out and check how much light passes through. Replace disposable filters immediately with the correct size and recommended MERV rating; consider reusable filters only if the furnace manufacturer approves them. If airflow is still limited after replacing the filter, blocked ducts, disconnected returns, or a failing blower are likely and should be checked by a professional.

| Symptom | Likely Cause | Immediate DIY Check / Recommended Next Step |

|---|---|---|

| Furnace runs but air is cold | Clogged filter or closed vents | Replace the filter, open returns and supply registers, then retest |

| Heat cycles on briefly then blower runs cold | Limit switch tripped from restricted airflow | Replace the filter; if the problem continues, call for duct/blower inspection |

| Intermittent warm then cold air | Partial combustion or ignition fault | Watch the ignition sequence; if there’s no flame, follow igniter checks or call a pro |

This table helps you triage cold‑air problems quickly. If these DIY checks don’t restore warm airflow, schedule a professional maintenance visit to diagnose blower motor or ductwork issues.

Blower motor and limit switch issues

If the blower runs while burners are off, it will move unheated air — often because safety circuits cut fuel when the heat exchanger overheats or because the motor isn’t reaching the proper speed. Start by checking the furnace power switch and your home breaker for trips, then listen for unusual blower noises like grinding, squealing, or rattling that suggest bearing or capacitor problems. If you smell burning or see smoke, turn the unit off, leave the area, and call for professional help immediately. If the blower won’t start or just hums despite normal power, don’t try to repair the motor yourself — call a trained technician to check windings, capacitors, and the limit switch.

What causes furnace short cycling and how can I stop it?

Short cycling — frequent on/off cycles that are shorter than normal — lowers efficiency, increases wear, and often points to a control, airflow, or ignition problem. The furnace may reach a safety or perceived setpoint too quickly and shut down, or a flame problem can trigger repeated restarts. Common causes include oversized equipment, dirty filters, faulty flame sensors causing lockouts, or a thermostat placed where it senses the wrong temperature. Fixing the root cause protects your equipment and cuts energy costs. Below are practical fixes and preventive steps to stop short cycling.

Research shows that fixing operational faults in HVAC systems significantly improves efficiency and lowers energy use.

HVAC System Faults: Diagnosis for Energy Efficiency

Building HVAC systems account for more than 30% of annual energy consumption in the United States. Studies have found that operational faults are a major cause of poor system performance. Fixing faults and optimizing controls can deliver an estimated energy savings of 5 to 15 percent.

Key steps to diagnose and reduce short cycling:

- Replace or clean filters and ensure vents and returns are clear.

- Check thermostat operation and placement — avoid heat sources and direct sun near the thermostat.

- Clean the flame sensor or schedule a professional replacement if cycling keeps happening.

Cleaning or replacing simple parts often stops cycling. If the issue is incorrect equipment sizing or repeated lockouts, get a professional evaluation and consider component replacements or control changes to prevent recurring cycles.

Thermostat faults and equipment sizing

A thermostat placed near heat sources, in direct sunlight, or next to a supply register can read false warmth and shut the furnace off too soon, causing short cycles. To test, put a portable thermometer near the thermostat and compare readings. On older thermostats, try adjusting the differential or anticipator settings. For wireless or smart thermostats, check firmware and battery health — automation routines or network issues can cause erratic behavior. If diagnostics suggest the furnace is oversized for the home, a professional load calculation and possible equipment or control changes may be needed.

Flame sensor issues and dirty filters

The flame sensor confirms continuous combustion; when it becomes coated with soot or oxidized, the control board can think the flame is out and shut off the burners, causing repeated start/stop cycles. You might see the furnace try to ignite and then shut down after a few seconds. If you’re comfortable working safely and the unit is powered off, you can gently clean the sensor with a fine abrasive pad — but be careful, the sensor is fragile and sits inside the burner area. If cycling continues after cleaning or you notice frequent lockouts, call a technician for safe replacement and a deeper combustion inspection.

How do I troubleshoot ignition, pilot light, and the flame sensor?

Older furnaces with standing pilots and modern units with electronic igniters fail in different ways, but both stop safe combustion when ignition fails. Troubleshooting follows a safety-first sequence: check for a gas smell, verify igniter or pilot status, and watch flame behavior and control-board responses. If you smell gas, hear repeated ignition attempts with no steady flame, or see control-board lockouts, stop and call a professional. The sections below walk through pilot/igniter checks and non-invasive control-board observations you can use to prepare for a service call.

Pilot light out and ignition problems

For furnaces with a standing pilot, a pilot that won’t stay lit can mean a bad thermocouple, a blocked pilot orifice, or gas-pressure issues. Modern electronic igniters typically show no glow or no click when they fail. If you smell gas, evacuate immediately and call emergency services — do not relight. For no‑smell, no‑heat situations, watch the ignition sequence through the access panel: the igniter should glow or the pilot should light when the thermostat calls. If you see sparking but no ignition, the gas valve might not be opening or the igniter could be weak. Repeated failed attempts or a visibly damaged igniter are clear reasons to stop and schedule professional heating repair and gas‑supply diagnostics; document what you saw for the technician.

Thermostat and control board checks

Control boards often use diagnostic LEDs or error codes to point to ignition and safety faults. Record flashing patterns and counts before power‑cycling — that information helps a technician diagnose faster. Non‑invasive checks you can do include confirming furnace power, checking for blown low‑voltage fuses near the control board, and photographing any status lights or labels. Don’t probe live terminals or attempt board repairs yourself; use your observations to give the technician a clear report. If errors persist after basic resets or multiple components fail, a professional diagnostic is the safe next step.

How to read furnace error codes and know when to call a pro

Error codes and LED flash patterns are your furnace’s way of saying what’s wrong — learning to read them reduces guesswork and gets the right fix faster. Codes typically point to ignition failures, flame sensor problems, limit trips, or communication errors. Each code has DIY checks you can safely try and clear thresholds that mean you should call a professional. The table below maps common faults to quick homeowner actions and when to call for service.

| Error / Component | Possible Cause | DIY Action / When to Call Pro |

|---|---|---|

| Ignition lockout (repeated flashes) | Igniter or gas valve failure | Power‑cycle once and check gas supply; call a pro if it repeats |

| Flame sensor fault (single flash pattern) | Dirty or failing flame sensor | Clean the sensor if comfortable; call a tech if it keeps happening |

| High‑limit trip | Restricted airflow or blocked return | Replace the filter and check vents; call a pro for duct/blower inspection |

| Control communication error | Faulty board or wiring | Note the flashing pattern and photograph LEDs; call a pro for diagnostics |

Common error codes across major brands

Manufacturers use different numbers, but the same problems pop up across brands: igniter/ignition faults, flame sensing issues, pressure‑switch and limit‑switch trips, and control‑board communication errors. Write down the furnace model and the exact LED flash count or digital code before you try a reset. Limit yourself to non‑invasive actions like replacing filters or a single power‑cycle. If the code returns or you’re unsure, don’t keep resetting — call a technician. Photos and a brief timeline of events speed up their troubleshooting when they arrive.

| Code Example | Typical Meaning | Homeowner Check / Call Pro Threshold |

|---|---|---|

| Flash pattern 3 (ignition) | Igniter or gas valve | Check gas supply and power‑cycle; call a pro if the problem continues |

| Flash pattern 2 (flame sensor) | Flame sensing fault | Clean the sensor if able; call a pro for replacement if needed |

| Solid LED + error | Control fault | Record the status and call a pro for board diagnostics |

Gas safety, emergency indicators, and when to call for help

Gas‑related signs need immediate, safety‑first action. If you smell gas, hear hissing, have a CO alarm, or see flame discoloration or heavy soot, evacuate and contact emergency responders or your gas utility before any HVAC work. Never try to repair gas valves, fittings, or combustion chambers yourself. Other red flags that require professional response include repeated ignition lockouts, visible heat‑exchanger cracks (rust, soot, or odd odors), or electrical burning smells. If you have any doubt about combustion safety or gas integrity, evacuate and get a professional assessment right away.

| Emergency Indicator | Action Required | Who to Contact |

|---|---|---|

| Smell of gas | Evacuate and call emergency services or the gas company | Emergency responders / gas utility |

| CO alarm activation | Evacuate, ventilate from a safe location, and seek immediate help | Emergency services and an HVAC professional |

| Repeated lockouts | Turn off the unit and schedule immediate service | Licensed HVAC technician |

Need local help? One Call Heating & Cooling serves McDonough and nearby areas with heating repair and emergency response. Our team handles repairs, installations, and maintenance across McDonough, Locust Grove, Fayetteville, Stockbridge, and Conyers, GA, and offers weekend emergency availability for no‑heat situations. If your DIY checks don’t restore safe heating or error codes point to gas or combustion faults, call a licensed local technician — have recorded error codes and notes ready when you call ((678) 759-2363).

Many homeowners avoid emergency repairs with scheduled maintenance. Below is a short maintenance reference that ties routine tasks to frequency and benefits.

| Maintenance Task | Frequency | Benefit / Service Offer |

|---|---|---|

| Replace disposable air filter | Every 1–3 months | Keeps airflow steady and reduces limit trips; professional filter replacement available |

| Annual tune‑up and safety inspection | Annually | Verifies ignition, combustion, and controls are safe; includes diagnostic checks |

| Clean flame sensor and burners | Annually or as needed | Reduces lockouts and improves ignition reliability; technician cleaning recommended |

Regular maintenance cuts emergency repairs and extends equipment life. Consider a maintenance plan to keep your system reliable all season.

Why choose One Call Heating & Cooling: we offer complete service — installation, repair, and maintenance — backed by local knowledge and weekend emergency coverage. Our customer‑first approach includes flexible financing and service across nearby cities. For persistent or unsafe furnace issues that DIY steps can’t fix, schedule professional diagnostics with our local technicians who safely handle combustion and control problems. Call (678) 759-2363 to arrange service or emergency response.

- Check filters and vents regularly — this prevents most airflow-related problems.

- Record error codes and symptoms before you call a technician to speed repairs.

- Put safety first — evacuate and call emergency services for gas smells or CO alarms.

Frequently Asked Questions

What are the signs that my furnace needs professional maintenance?

Call a pro if you hear unusual noises like grinding or squealing, if the furnace short cycles frequently, heating is inconsistent, or you notice a gas smell. Blowing cold air while set to heat or frequent ignition lockouts are also signs a technician should inspect the system. Regular maintenance helps prevent these problems.

How often should I replace my furnace filter?

Replace disposable filters every 1 to 3 months, depending on use and filter type. Homes with pets or high dust may need more frequent changes. Regular filter changes keep airflow steady, improve efficiency, and reduce overheating risks. Check your furnace manufacturer’s recommendations for filter types and intervals.

Can I troubleshoot my furnace if it’s making strange noises?

Yes — start by turning off the unit and checking for loose panels or debris around the blower. Grinding often points to worn bearings; rattling can mean loose hardware. If the sounds continue or you smell burning, shut the unit down and call a technician to avoid further damage or safety risks.

What should I do if my furnace keeps shutting off?

If your furnace keeps shutting off, it may be short cycling. First, check and replace the air filter and make sure vents aren’t blocked. Inspect thermostat placement and settings. If the problem continues, have a professional check for limit switch faults or other critical component issues.

How can I improve my furnace's energy efficiency?

Improve efficiency with regular maintenance: replace filters, schedule annual tune‑ups, and make sure your home is well insulated. A programmable or smart thermostat helps optimize heating schedules. Sealing ductwork leaks and keeping vents clear also boosts performance and lowers energy bills.

What are the risks of ignoring furnace maintenance?

Skipping maintenance can lead to reduced efficiency, higher energy bills, and unexpected breakdowns. Neglected systems can also become safety hazards, including gas leaks or carbon monoxide risk. Regular maintenance finds small issues before they become costly or dangerous. Our HVAC services can help.

When should I consider replacing my furnace instead of repairing it?

Consider replacement if your furnace is over 15 years old, needs frequent repairs, or if repair costs approach half the price of a new unit. Upgrading to a more efficient model can lower energy bills and offer long‑term savings. A technician can assess your system and recommend the best option.

Conclusion

Knowing basic furnace troubleshooting lets you identify and resolve many common heating issues and keeps your home safe and comfortable. Simple checks — thermostat, power, and filter — fix many problems, and clear signs tell you when to call a pro. If an issue feels unsafe or persists after DIY steps, contact a licensed technician. For more tips and support, explore our resources or give One Call Heating & Cooling a call.